Definition

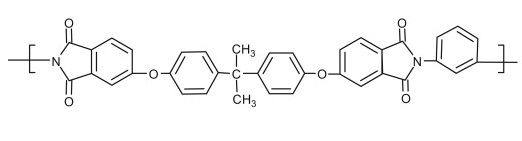

PEI (Polyetherimide) is an amorphous amber-to-transparent engineering thermoplastic. The molecular formula of PEI is C37H24O6N2. Owing to its high temperature resistance and tensile strength, dimensional stability, excellent flame resistance and low smoke emission, PEI has been an ideal material used in the automotive, electrical, medical and other industrial fields. It is also a promising material in the drug delivery field.

PEI Molecular Strcuture

Properties

High deflection temperature

High tensile strength and flexural modulus

High flame resistance

Unique combination of high specific strength, rigidity, flexibility and exceptional dimensional strength

Good electrical stability

Good UV-light resistance and weatherability

Good hydrolytic stability

Resistance against alcohols, acids, and hydrocarbon solvent

Mechanical strength, electrical insulation and radiation resistance

Chemical resistance

Synthesis

Polyetherimide (PEI) is typically synthesized via a polymerization reaction. The most common route for the synthesis of PEI is the reaction between 4,4′-diaminodiphenyl ether and 3,3′,4,4′-benzophenonetetracarboxylic dianhydride. Here are the steps for the synthesis of PEI:

Preparation of Diamine and Dianhydride Solutions

Polymerization Reaction: The polymerization reaction should be processed using the combination of the diamine solution and the dianhydride solution in a high-temperature reaction vessel under an inert atmosphere.

Heating and Condensation: The reaction mixture is heated to a specific temperature (typically above 200°C) and maintained for a certain period. During this step, the polyetherimide polymer chains will be formed through a condensation polymerization process.

Cooling and Solidification: After the polymerization reaction is completed, the mixture should be cooled down. The resulting polymer solution starts to solidify as the polymer chains crosslink and form a three-dimensional network.

Isolation and Processing: The solidified polymer is typically recovered, washed to remove any residual solvents or byproducts, and then processed into the desired form (pellets, sheets, etc.).

Applications in Drug Delivery

Due to its biocompatibility, tunable properties and ability to encapsulate and release drugs in a controlled manner, PEI has shown promise in drug delivery, improving the solubility, stability and targeted delivery of therapeutic agents.

Nanoparticles and Nanocarriers: PEI can be used to formulate nanoparticles or nanocarriers by encapsulating drugs within their structure to protect the drug from degradation, enhance its solubility and enable controlled release.

Gene Delivery: PEI’s positive charge makes it suitable for complexing with negatively charged nucleic acids, such as DNA and RNA. PEI-based vectors are able to form nanoparticles that protect genetic material and facilitate its intracellular delivery.

Micelles: Due to its amphiphilic nature, PEI can form micelles in aqueous solutions, which can be used to encapsulate hydrophobic drugs within their core, enhancing drug solubility and stability.

Hydrogels: PEI can be incorporated into hydrogel formulations, creating three-dimensional networks that can encapsulate and release drugs over time.

Coatings and Films: PEI coatings or films can be applied to medical devices, implants and drug-eluting stents to control the release of drugs at a specific rate over time. It can reduce the need for frequent drug administration and improve patient compliance.

Combination Therapies: PEI-based drug delivery systems can be designed for combination therapies, where multiple drugs with different properties are delivered together to enhance treatment effectiveness.

Targeted Delivery: By modifying the surface properties of PEI-based carriers, such as attaching targeting ligands or antibodies, targeted delivery to specific cells or tissues can be achieved, reducing off-target effects and improving therapeutic efficacy.